Broiler Feed Formulation Amid Coronavirus Outbreak

Sandro Cerrate, PhD

Credinser LLC, Madison, Alabama

Published: April 17, 2020

During these difficult times facing the coronavirus outbreak, the poultry producers are acting toward the abrupt drop of broiler meat prices. Further, the reduction of chicken sales has forced some farms to decrease their poultry production. Under this circumstance, poultry farmers are increasing their biosecurity and becoming more efficient by reducing the feed cost or costs related to poultry production. One of the main questions is, how many do we need to decrease the nutrients using feed formulation due to reduced meat prices?

Outlining potential scenarios by formulating reduction of energy and amino acids and by predicting the feed conversion will result in the maximum profit feed formulation using the current feed ingredient and broiler meat prices. Nutritionists apply these types of formulation running several internal nutrient levels to know the impact on the broiler performance, under their environment, feed, genetic, and management conditions.

For some companies with fewer resources for running studies, they need to know which is the maximum profit feed formulation during the coronavirus pandemic. They might use historical data, published in the literature, about the effect of nutrient density on feed conversion. In addition, both large and small poultry companies require using those past broiler performances to know which nutrient levels will yield the best economic scenarios.

This article describes three topics to know the best broiler feed formulation amid coronavirus outbreak, such as (a) current meat and ingredient prices, the (b) formulation for maximizing profitability, and the (c) economic nutrients due to reduced broiler meat prices.

a) Current meat and ingredient prices

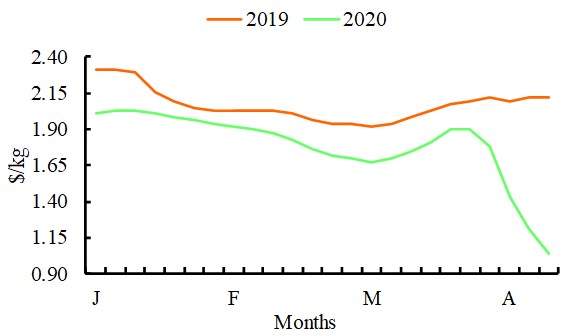

The total and partial quarantine imposes for some governments have produced a reduction of meat consumption in restaurants or stores. This event mainly is the cause of a drop in broiler chicken prices. For example, the US broiler meat price of the first week of 2020 April has decreased sharply by around 50% as compared to ones from March 2019 (Figure 1). Similarly, in other countries like India, broiler meat prices have crashed even more, by 60% (Raj, 2020).

Figure 1. Meat broiler prices of composite weighted average (USDA, 2020).

Note: J = January; F = February; M = March; A = April.

In contrast, the corn and soybean meal commodities have not reduced their prices at the same intensity as broiler meat prices. Soybean meal price has similar prices as past months, whereas the corn prices have decreased by 10% as compared to those from March during 2020 (Market Insider, 2020). This reduction of corn price responded to the less ethanol demand resulting from the coronavirus (Sjerven, 2020).

If these meat prices will remain in the lows for some months, the nutritionist might adjust the broiler diets according to these reduced broiler prices. However, the prices for soybean and corn will not result in significant changes for the broiler feeds. One approach for including this new meat price is projecting the income and cost during the formulation by using non-linear programming to calculate the profitability.

b) Formulation for maximizing profitability

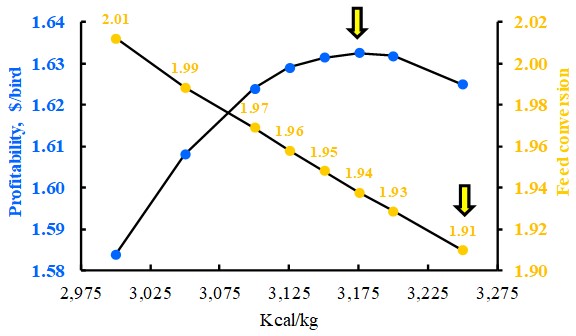

Measurements of body weight and feed intake are essential inputs for calculating income and cost. For instance, the broiler price and body weight account for the income, whereas feed intake and diet costs explain feed costs. Using this simple relationship between income and cost, the feed intake and body weights respond to changes in nutrients, and the meat and ingredient prices influence the profitability also. Thus, for each particular nutrient levels, the profitability is calculated as follow:

Profitability, $/bird = meat price ($/kg) x body weight (kg) – diet cost ($/kg) x feed intake (kg)

Using this equation, when the energy level was 3,175 kcal/kg, the profitability peaked (Figure 2), even though the feed conversion was not the best output (Figure 2). In this study, the energy and amino acid were increased at the same proportion, also named dietary nutrient density (Cerrate and Waldroup, 2009a). Thereby, these body weights and feed intakes calculated by polynomial equations were in function of the dietary nutrient density.

Figure 2. Maximum profit and feed conversion.

Note: Yellow arrows indicate the highest profitability and also the best feed conversion.

There are several types of economic models that describe this simple equation, with some variation though with a similar concept. These types of maximum profit feed formulation rely on knowing in advance the broiler meat prices that for yielding the highest profitability is a great advantage. However, when the broiler price at the beginning of the broiler campaign is drastically different from the one at the time of sale, economic nutrients might not produce the highest profits.

Therefore, this kind of broiler feed formulation works best when the broiler meat prices are stables or easy to predict. You might think that using the broiler price in the feed formulation is risky. Nevertheless, Cerrate and Waldroup (2009a) demonstrated that, for 12 months in 65’000,000 birds per year, the maximum profit feed formulation using broiler prices at the beginning of the broiler campaign yielded around 76,000 dollars over the least cost feed formulation.

Usually, large poultry companies test internally broiler trials for evaluating the best economic nutrients subjected to particular management, environment, genetic, and feed. After knowing the results, these companies find the best economic nutrients that report the highest profitability. In other words, many large poultry companies are using the maximum profit concept and finding the best nutrient by approximation, without implanting the polynomial equations. Here opens an opportunity to use their biological performance and develop simple polynomial equations for predicting the feed intake and body weight linking with the nutritional levels.

During this coronavirus outbreak that mainly disrupted the broiler meat prices, this type of formulation might indicate a direction for economic energy and amino acids in the broiler feed formulation. These nutrients influence mostly feed costs. Furthermore, nutritionists should explore other nutrients or additives, apart from energy and amino acids, that influence curvilinearly the body weight and feed intake without affecting the immunity and mortality.

c) Economic nutrients due to reduced broiler meat prices

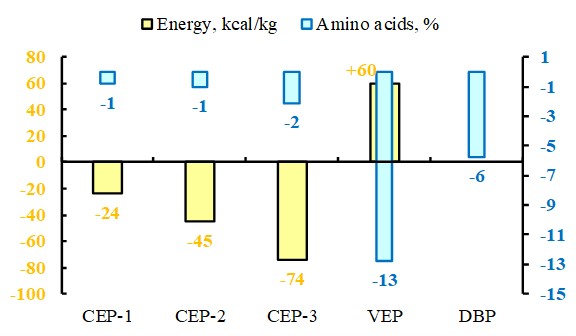

In the current course of coronavirus outbreaks, some meat producers have decreased their poultry production (Devenyns, 2020). In this scenario, some companies are reducing their nutrients to slow down chicken growth. According to these trends, scientists have simulated several economic scenarios for variation of broiler meat prices finding reductions in energy by 24 kcal/kg (Guevara, 2004), by 45 kcal/kg (Cerrate and Waldroup, 2009a), and by 74 kcal/kg (Cerrate and Waldroup, 2009b) during a 50% drop of broiler meat price. In those economic models, the energy and protein were constant; as a result, the reduction in amino acids or protein was between 1 and 2%. In general, during these formulations, the feed costs were lower for compensating the drop of broiler prices.

In agreement with these reductions of feed costs, another economic model based on variable energy and protein increased the energy content by 60 kcal/kg and reduced the amino acids by 13% largely (Figure 3). This fluctuation of nutrients increased the broiler abdominal fats more than expected, impacting the meat quality due to higher energy to protein ratio. For this reason, this is not the best economic model during these broiler meat prices. On the other hand, when the economic model varied only the dietary balanced protein, the amino acids decreased by 6% due to the loss of 50% in meat price (Cerrate and Waldroup, 2009b). The balanced protein is also known as the ideal protein, in which the essential amino acids produce the dietary protein content.

Figure 3. Economic nutrient contents when broiler meat is reduced in 50%.

Note: CEP = constant energy and protein, VEP = variable energy and protein, DBP = dietary balance protein. Simulations of CEP-1 from Guevara, (2004); CEP-2 from Cerrate and Waldroup (2009a); and CEP-3, VEP, and DBP from Cerrate and Waldroup (2009b).

As expected, these new economic nutrients will improve the profitability, notwithstanding that the feed conversion will increase between 0.02 and 0.05 hundredths, or 2 and 5 points.

A wide range of variables affects the assigned nutrient values such as genetic broiler chickens (Cerrate and Corzo, 2019), the environment temperature, and feed form (Cerrate and Waldroup, 2010 a,b). Therefore, large companies should use their past research studies and outline economic scenarios or build equations to calculate the best energy and amino acids which support the maximum profitability. Otherwise, for small poultry companies, who don’t have resources to run studies amid the coronavirus outbreak, might reduce the energy by 50 kcal/kg and amino acids by 2%.

Conclusions:

- If broiler meat prices are kept 50% less amid coronavirus outbreak for the coming months, poultry producers should take actions in their broiler diets.

- The economic nutrients using the maximum profit broiler feed formulations seem the best option during this coronavirus pandemic; despite, these changes will not yield the best biological response.

- Large poultry companies should quantify from previous trials and develop equations to find the best economic nutrients for energy and amino acids, at the same time, small poultry companies might reduce the energy by 50 kcal and amino acids by 2%.

The author declares that this article was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest. Every attempt has been made to ensure that the material in this article is accurate, true, correct, and relevant at the time of writing. However, the author accepts no liability for any omissions, damage, loss, or financial consequences of using this article.

Cerrate, S. and A. Corzo. 2019. Lysine and energy trends in feeding modern commercial broilers. Int. J. Poult. Sci. 18:28-38.

Cerrate, S. and P. Waldroup. 2009a. Maximum profit feed formulation of broilers: 1. Development of a feeding program model to predict profitability using non-linear programming. Int. J. Poult. Sci. 8:205-215.

Cerrate, S. and P. Waldroup. 2009b. Maximum profit feed formulation of broilers: 2. Comparison among different nutritional models. Int. J. Poult. Sci. 8:216-228.

Cerrate, S. and P. Waldroup. 2010a. Maximum profit feed formulation. 4. Interaction between energy content and feed form. Int. J. Poult. Sci. 9:641-647.

Cerrate, S. and P. Waldroup. 2010b. Maximum profit feed formulation 3. Interaction between energy content and 1emperature. Int. J. Poult. Sci. 9:634-640.

Devenyns, J. 2020. More Meat Plants Close as Employee Coronavirus outbreaks Grow. April 9th. From https://www.fooddive.com/news/more-meat-plants-close-as-employee-coronavirus-outbreaks-grow/575752/

Guevara, V. R. 2004. Use of nonlinear programming to optimize performance response to energy density in broiler feed formulation. Poult. Sci. 83:147-151.

Marker Insider. 2020. Corn Commodities. https://markets.businessinsider.com/commodities/corn-price. Retrieved, April 13.

Marker Insider. 2020. Soybean Commodities. https://markets.businessinsider.com/commodities/soybeans-price. Retrieved, April 13.

Raj, G. 2020. Covid-19 Impact: Though Times for Poultry Farmers as Prices Crash by 60%. March 6th. From https://www.deccanherald.com/state/karnataka-districts/ambulance-seized-for-transporting-youths-825438.html

Sjerven, J. 2020. Larger 2019-20 US corn, wheat and soybean carryover forecasts. April 4th. From https://www.foodbusinessnews.net/articles/15800-larger-2019-20-us-corn-wheat-and-soybean-carryover-forecasts.

USDA. 2020. Broiler Market News Report. April 10

Interesting and very timely. Thanks for the insight into how producers are responding to this situation, and deciding how to modify their formulations